Comprehensive Wastewater Solutions

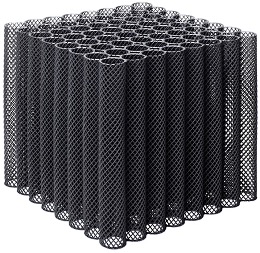

MBBR Media & Biofilters

High-performance MBBR biofilter media with exceptional mechanical properties, optimal density, and excellent biofilm growth for efficient wastewater treatment. >> Read More

Aeration & Diffuser Systems

Fine and coarse bubble diffusers, tube and panel systems with high oxygen transfer efficiency and energy-efficient aeration solutions. >> Read More

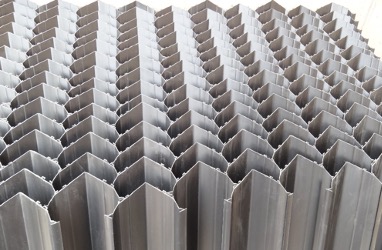

BIO-BLOK Filter Media

High specific surface area filter media that increases system efficiency, reduces footprint, and provides optimal conditions for biofilm growth. >> Read More

Bio Chip Technology

Small Boss MBBR biofilter media with excellent mechanical properties, high impact strength, and optimal density for wastewater treatment applications. >> Read More

Lamella Tube Settler Media

Tubular settlers and parallel plates that improve settling capacity by reducing vertical distance for flocculated particles in clarifiers and settling tanks. >> Read More

Coarse Bubble Diffusers

Crafted using latest technology for wastewater treatment plants with PP body, 30% GPR support, and 20-25% oxygen efficiency. >> Read More

Fine Bubble Disc Diffuser

Three-part disc diffusers with EPDM membranes, suitable for retractable systems, and warranting 35-45% oxygen efficiency. >> Read More

Tube Diffusers

Best solution for long and narrow aeration tanks with different material options, connection threads, and sizes for various wastewater types. >> Read More

Panel Diffuser

High-capacity diffusers with higher oxygen transfer efficiency, unique membrane diversity, and strong body for large treatment systems. >> Read More

Dewatering Bags

High-strength geotextile bags for effective dewatering of silt, sediment, sludge, and contaminated waste in all weather conditions. >> Read More